According to CISQ, poor-quality software in the US resulted in losses of over $2.41 trillion by 2022. This means one important question is what improvements in software development can be expected to reduce costs that are dramatically increasing? There are two integral processes in terms of quality control and quality assurance that are major determinants in producing quality goods and services.

Understanding the difference between the two processes is a great requirement for sustaining quality within an organization. In this blog, the difference between quality assurance and quality control are explained with regards to the contribution they provide during product development.

What is Quality Assurance?

Quality assurance is a systematic process designed to ensure that the products or services meet specified quality requirements and are free from defects. It is part of any organization in the pursuit to deliver the highest quality of solution.

QA focuses on prevention of quality problems by setting out clear processes that measure, track, and analyze the quality of a product or service. In addition to this, QA strives for continuous improvement that will assist in developing and perfecting processes to ensure constant quality standards.

What is Quality Control?

Quality control, or QC, is a procedure of defect detection and rectification in the products or services even before it is presented to the customer. The inspection and testing procedures will help ensure that the final output produced meets predetermined standards and specifications regarding quality.

QC is carried out in the production phase to identify and correct any inaccuracies that could compromise quality. This way, the product or service delivered to the customers is reliable, consistent, and up to their expectations.

Quality Assurance vs. Quality Control- Key Differences

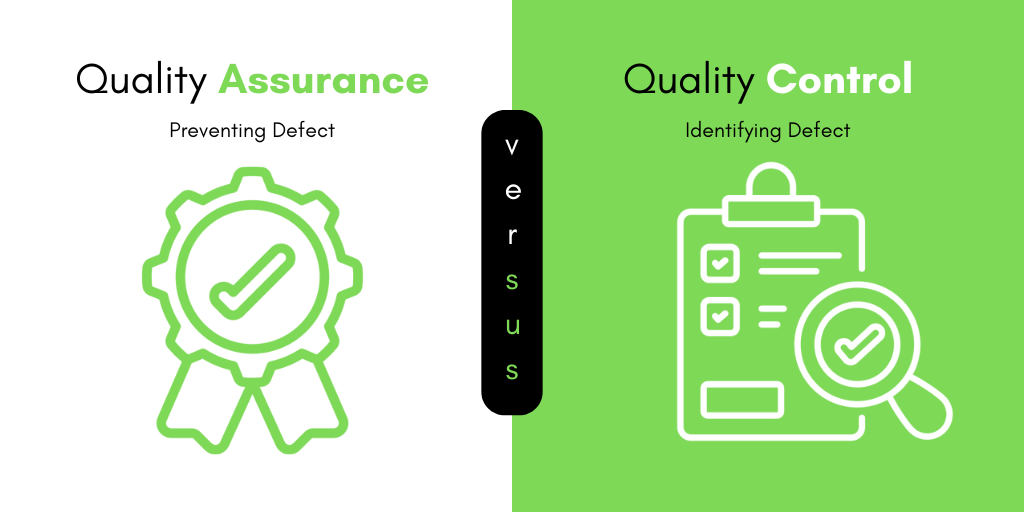

QA and QC are sometimes used collectively, but they are two different procedures in quality management:

- Quality assurance is preventive in nature because it deals with designing and implementing processes so that quality can be achieved at the onset. Quality control is corrective because it identifies defects in the final product or service and rectifies them.

- Quality assurance is proactive because it attempts to avoid quality issues before they are realized. Quality control is reactive because it attempts to rectify defects after production.

- Quality assurance also involves a broad scope, in the sense of process improvements as well as overall quality management plans. Quality control is more defined and limited and usually deals directly with product examination and testing.

Benefits of Quality Assurance and Quality Control

Introducing quality assurance (QA) and quality control (QC) programs provides extensive benefits that facilitate the success of an organization in the long term. These include:

- Quality delivery of the products or services provided for sale with satisfaction and extended customer loyalty.

- Saving on production cost by reducing expenditures on product failure and defects by ensuring that the products meet standards from the onset.

- Reinforcing a company's reputation as it shows dedication to quality and delivers products or services that match the expectations of customers.

- Improving production efficiency by reducing the time taken for manufacturing, inspection, and testing.

- Enabling continuous improvement by allowing organizations to find, correct, and track quality problems so changes can be implemented and processes enhanced over time.

Quality Assurance vs. Quality Control – Timeline

Now that we have discussed the differences and benefits of QA and QC, let's look at the different timelines associated with each process.

Quality Assurance Process

Quality assurance ensures products and services are standardized and meet customer expectations. The following is how the process of quality assurance goes:

Define Quality Standards and Requirements : Define the required quality benchmark and expectations of what the product or service should be.

Design Quality Control Processes : Develop monitoring and control processes, including tooling, techniques, and equipment utilization.

Implement Quality Control Processes : Implement quality control as defined in the process during production so that finished products and services attain the standards set.

Conduct Quality Audits and Inspections : Systematically check products and services to identify potential problems and defects by conducting audits and inspections.

Continuously Improve : In light of auditing, inspection data, and even customer feedback information, improvement avenues are sought while refining the process to the exact quality levels being expected.

Quality Control Process

Quality control represents the process that a company utilizes in systematically examining finished goods or services for identifying defects for customer use. These steps include:

Specify the quality standards and requirements : Indicate the general quality standards set for the finished product or service.

Outline specifications of products or services : Elaborate detailed specifications and list the set parameters of needed quality.

Develop Quality Control Plan : Formulate the inspection and testing criteria for ensuring meeting quality standards.

Implement Quality Control Activities : Inspect, analyse, and test products or service throughout the production process.

Analyse Data, Detect Errors : Assess quality control data to identify and correct possible defects or inconsistencies.

Take Corrective Action : Implement solutions with the objective of correcting defects and preventing their occurrence in the future.

Quality Assurance vs. Quality Control – Practices

Now that we have studied the timelines of quality assurance and quality control, let us now look at the many approaches that an organization uses to implement these processes effectively.

Quality Assurance Approaches

Quality assurance involves several methodologies which ensure that products and services offered meet quality standards and are in line with the expectations of the customers. Some of the most commonly used QA approaches include:

Total Quality Management (TQM) : It is the process of continuous improvement and all the employees in the organization have a role to maintain high quality.

Six Sigma : This methodology relies on data analysis and statistical methods to minimize defects and improve quality of product or service.

Plan-Do-Check-Act Cycle : PDCA Cycle (Deming cycle) emphasizes continuous improvement in production, which has four stages: planning, implementation, monitoring, and refining processes based on results.

Lean Manufacturing : Reduces waste in the production process with an aim of enhancing the efficiency of manufacturing to improve product quality.

Theory of Constraints (TOC) : Finds and eliminates bottlenecks within the production process for overall quality and efficiency.

Agile Methodology : This method is mainly used in software development. Agile method emphasizes the iterative and incremental development cycles, which ensure high-quality outputs.

ISO Standards Compliance (e.g., ISO 9001) : Organizations adopt ISO standards for compliance with the international requirements on quality. In this regard, it maintains uniformity, satisfaction of customers, and constant improvement.

Quality Control Approaches

Quality control focuses on the detection of defects in the finished products or services. Organizations use different approaches to QC in order to ensure that their outputs meet the required quality standards. Some of the approaches include:

Statistical Process Control, or SPC : Uses statistics to monitor manufacturing quality and in real-time measure deviations from those standards.

Taguchi Method : Developed by Genichi Taguchi, designed to integrate methods of statistics right into the conception and development stage of a product to improve quality and reduce sensitivities to small variations.

Inspection : Involves checking on finished products or services whether it is done visually, physically, or by automated systems to ensure whether they are up to quality standards.

Quality Circles : A group approach where employees volunteer to work together to identify defects and improve the quality of production.

Checklists : A structured approach that involves listing quality criteria and verifying that each requirement is met before the product is approved for release.

Conclusion

Quality assurance and quality control are integral parts of any effective quality management system. Being common in the sense that they both aim at delivering quality products and services, they differ in scope and approach: quality assurance is proactive whereas quality control is reactive, as it tends to find problems after making the product.